Future of PCB Technology: HDI Boards, AI Manufacturing, and Biodegradable Materials

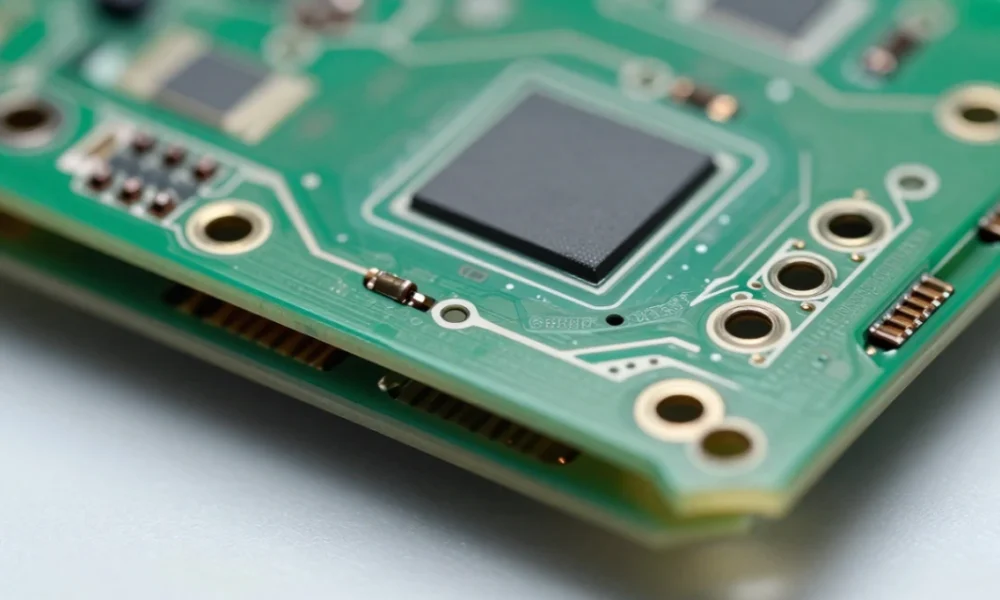

The printed circuit board has progressed from rudimentary point-to-point wiring systems to sophisticated multi-layer structures that power today’s most advanced devices. Understanding this progression provides essential context for where the technology is headed.

Table Of Content

- Critical Technological Breakthroughs

- High-Density Interconnect Technology

- Advanced Material Development

- Artificial Intelligence in PCB Manufacturing

- Flexible and Stretchable Electronics

- 3D Printed Electronics and Additive Manufacturing

- Embedded Component Technology

- Biodegradable PCB Substrates

- IoT and Miniaturization Requirements

- 5G and High-Frequency Applications

- High-Power PCB Applications

- Global Market Dynamics

- Manufacturing Challenges

- Manufacturing Process Advancements

- Smart PCBs with Integrated Functionality

- Industry Investment and Capacity Expansion

- Future Outlook

Early electronic devices relied on metal or non-conductive chassis with components wired individually. This primitive breadboard approach proved unreliable—any physical disturbance could cause short circuits.

PCB adoption accelerated during World War II. Austrian engineer Paul Eisler invented the printed circuit in 1936 as part of a radio set while working in the UK. By 1941, German engineers used multi-layer printed circuits in magnetic-influenced naval mines. Around 1943, the United States deployed this technology for proximity fuzes that required durable circuits capable of withstanding gun-fired impacts while enabling mass production.

The Centralab Division of Globe Union developed a solution using ceramic plates screen-printed with metallic paint for conductors and carbon material for resistors, with ceramic disc capacitors and subminiature vacuum tubes soldered in place. This approach succeeded, and the U.S. Army classified the patent, assigning it to Globe Union. In 1984, Harry W. Rubinstein received the Cledo Brunetti Award from the Institute of Electrical and Electronics Engineers (IEEE) for his contributions to printed components and conductors on insulating substrates. The University of Wisconsin-Madison honored him that year for advancing printed electronic circuits and capacitor fabrication.

Critical Technological Breakthroughs

The introduction of multi-layer PCBs allowed greater design complexity by stacking conductive material layers. This capability became essential as electronics grew more sophisticated, enabling compact yet powerful devices.

Surface mount technology (SMT) adoption in the 1980s transformed assembly. SMT allowed components to mount directly onto PCB surfaces, increasing component density and supporting miniaturization trends. These milestones continually pushed fabrication techniques to meet growing industry demands.

High-Density Interconnect Technology

HDI PCBs represent the most significant advancement in modern board technology. These boards feature microvias (typically under 150 µm), blind and buried vias, and fine lines under 100 µm, achieving wiring densities exceeding 130 connections per square inch compared to 50-70 connections in traditional boards.

The global HDI PCB market reached $16.2 billion in 2024 and is projected to grow to approximately $40 billion by 2032. HDI configurations include 1+N+1 (single microvia layer on each side), 2+N+2 (two microvia layers), and Any-Layer Interconnect (ALIC) systems where all layers interconnect freely. Every-Layer Interconnect (ELIC) technology provides similar capabilities with different structural approaches.

Manufacturers like Unimicron, TTM Technologies, AT&S, and Jabil lead HDI production. Applications span smartphones (where Apple’s iPhone models utilize stacked microvia technology), automotive ADAS systems, and medical devices. Sequential lamination processes add layer pairs incrementally, incorporating microvias and buried vias at each stage.

Via-in-pad technology places components directly over vias, critical for fine-pitch BGA packages. HDI boards enable higher routing capabilities, lower power consumption, and simpler stackups while supporting faster signal transmission speeds.

Advanced Material Development

Modern boards utilize laminates providing superior heat resistance and mechanical strength. High-frequency applications for 5G and telecommunications require specialized materials with low dielectric loss and stable electrical properties.

Rogers 4000 series laminates and PTFE-based (Teflon) substrates have gained widespread adoption for RF and microwave applications due to their signal integrity at elevated frequencies. Metal Core PCBs (MCPCBs) deliver exceptional heat dissipation for LED and power electronics applications. Ceramic substrates offer superior thermal conductivity and electrical insulation for aerospace and defense systems.

Flexible substrates like polyimide and polyester enable bending and conforming to various shapes. The flexible PCB segment is projected to reach $27 billion, growing faster than rigid counterparts. Liquid Crystal Polymer (LCP) materials provide excellent dimensional stability and moisture resistance for high-frequency applications.

Conductive nanoinks enable precise, low-resistance pathways that improve electrical performance in custom manufacturing. These materials allow boards to operate under demanding conditions while maintaining reliability.

Artificial Intelligence in PCB Manufacturing

AI has become central to design and manufacturing processes. Machine learning algorithms analyze thousands of existing designs to identify optimal component placement patterns. AI-powered routing systems suggest efficient trace paths, reducing overall length by up to 20% and improving signal integrity.

Tools like Circuit Mind, JITX, Cadence Allegro X AI, and Zuken AIPR automate placement and routing tasks, reducing completion time from days to minutes. AI enables predictive defect detection during manufacturing, analyzing sensor data to identify soldering defects, misalignments, and manufacturing discrepancies before boards leave production. Studies suggest AI-driven analytics can improve operational efficiency by as much as 20%.

Reinforcement learning approaches allow algorithms to learn from previous designs and automatically suggest optimal layout configurations. Digital twin technology—virtual replicas of products or processes—uses AI to simulate board behavior throughout its lifecycle, identifying potential problems before they manifest.

Flexible and Stretchable Electronics

Flexible PCB technology continues expanding beyond traditional applications. These boards enable foldable smartphones, smartwatches, and medical patches that monitor health metrics in real-time. Flexible boards offer traditional board reliability with added flexibility for devices requiring dynamic movement.

Flexible circuits handle repeated motion and are essential for wearables, LED strip lighting, medical instrumentation (including pill-sized cameras for digestive tract imaging), and surveillance applications. They reduce connector use, improve reliability, and reduce assembly time while remaining lightweight.

Rigid-flex PCBs merge the durability of rigid boards with the flexibility of dynamic circuits, offering unprecedented design possibilities for aerospace systems and industrial robotics where stress and vibration are regular occurrences.

3D Printed Electronics and Additive Manufacturing

3D printing enables rapid prototyping and complex geometries with embedded components. Researchers recently printed system-on-chip microcontrollers with 7,000 times the memory of other flexible boards. Commercial systems create diodes, LEDs, and thin-film transistors from organic polymers.

This technology allows horizontal and vertical scaling of components once desired configurations are achieved. Conductive traces and insulating layers can be printed directly onto substrates, or even onto non-flat surfaces, enabling boards to be integrated into curved or irregular shapes. Polymers are easily functionalized, allowing manufacturers to tune electronic and optical properties according to requirements.

Material limitations and design constraints remain challenges, particularly for rigid semiconducting materials needed for different frequency bands. While still in early stages, 3D printed electronics are expected to lower production costs and reduce waste.

Embedded Component Technology

Embedding components directly within PCB layers reduces overall footprint and minimizes signal loss and electromagnetic interference. This approach proves crucial for creating smaller, more powerful devices.

Embedded capacitors and resistors improve performance by shortening signal paths and reducing parasitic inductance, leading to better signal integrity at high frequencies—often above 1 GHz, which is critical for Wi-Fi and Bluetooth connectivity. This technology cuts down on assembly costs and enhances reliability by minimizing the number of soldered connections.

Thermal management and repairability present ongoing challenges. Manufacturers continue addressing these through improved design methodologies while benefiting from reduced device size and better protection for sensitive components.

Biodegradable PCB Substrates

Environmental sustainability has become a critical concern in electronics manufacturing. Traditional PCB production involves hazardous materials and chemicals posing environmental risks.

Jiva Materials developed Soluboard®, the world’s first biodegradable PCB substrate made from natural fibers (jute, flax) embedded in a water-soluble polymer. Unlike conventional FR-4 boards, Soluboard® dissolves in 90°C water within 30 minutes, enabling recovery of electronic components and valuable metals.

The University of Glasgow validated that Soluboard® supports wireless transmission exceeding 4 GHz and handles data rates over 3 Gbps, proving eco-friendly substrates can match conventional material performance. Soluboard® achieves a 67% carbon footprint reduction compared to FR-4 PCBs—saving 11.42 kg of carbon per square meter. The material received UL94 V1 flammability certification and is compatible with standard fabrication processes including etching, electroplating, and drilling.

Infineon Technologies has deployed Soluboard® in over 500 evaluation and demo boards, testing sustainable designs in consumer and industrial applications. The company is exploring wider adoption while researching the reusability of discrete power devices recovered from dissolved boards.

Soluboard® currently supports double-sided boards with plated through-hole (PTH) technology. Jiva Materials has a technology roadmap for multilayer boards, though this capability is not expected for several years. Water-solubility limits its use in humid or outdoor environments.

Other sustainable initiatives include halogen-free laminates, bio-based substrates like CircElPaper (laminated paper foils), and closed-loop water systems that reduce manufacturing impact. Europe’s stringent environmental regulations continue pushing manufacturers toward sustainable materials and precision processes.

IoT and Miniaturization Requirements

The Internet of Things drives demand for tinier, more powerful boards capable of handling high component density in limited space. Wearable devices, remote monitoring systems, and connected sensors require boards that can support multiple functionalities while consuming minimal power.

Wireless PCBs for IoT devices eliminate complex RF components through proven wireless technologies, accelerating fabrication. Healthcare applications include flexible diagnostic patches and hearing aids. Industrial automation benefits from sensors that fit seamlessly into unconventional shapes. Smart home devices require boards that handle high-speed data transfer, low power consumption, and integration with multiple sensors.

5G and High-Frequency Applications

The 5G network rollout demands boards capable of handling higher frequencies and data rates. These applications require materials with low dielectric loss and stable electrical properties at high frequencies. PCBs must support data speeds exceeding 20 Gbps with minimal latency.

High-frequency PCB requirements extend beyond telecommunications to automotive radar systems, where ADAS technology requires precise signal integrity for safety-critical functions. Electric vehicle platforms incorporate increasing amounts of power and sensor circuitry, driving demand for specialized solutions.

High-Power PCB Applications

High-power PCBs are emerging as a significant design category, driven by demand for compact yet powerful electronic devices. These boards handle high levels of power and heat dissipation, enabling integration of advanced components such as power transistors, amplifiers, and high-wattage LEDs.

Advancements in manufacturing processes and materials have facilitated development of high-power PCBs with enhanced thermal management, reduced electrical losses, and improved overall performance. Electric vehicles, renewable energy systems, and industrial automation applications increasingly rely on high-power PCBs as these technologies depend heavily on power electronics.

Challenges include heat generation and electromagnetic interference (EMI) issues that require careful design consideration and advanced thermal management solutions.

Global Market Dynamics

The global PCB market reached $75.5 billion in 2025 and is projected to grow at a 5.24% CAGR through 2030, reaching approximately $104.58 billion by 2030. Multi-layer boards captured 40.7% market share in 2024, while HDI boards show the fastest growth trajectory.

Asia-Pacific dominates with over 40% market share, driven by manufacturing hubs in Taiwan, China, and South Korea. Taiwanese leader Unimicron reported AI-server exposure exceeding 30% of sales in 2025, with targets of 40% by 2026. China maintains volume scale advantages, though U.S. export controls on advanced semiconductors prompt “China + 1” outsourcing models.

North America commands approximately 4% of global output but experiences reshoring momentum through subsidies for military-grade boards. Europe, holding 6.4% market share in 2025, exhibits the fastest regional growth driven by automotive innovation, particularly EVs and ADAS systems, plus stringent environmental regulations spurring sustainable material adoption.

Consumer electronics remain the dominant force, requiring smaller boards with complex component placement. Automotive applications utilize advanced boards for EV battery systems, ADAS, and thermal regulation. Telecommunications and IoT sectors depend heavily on signal integrity and HDI solutions. Medical device demand increases for portable and implantable devices requiring miniaturization. Aerospace and defense sectors require high-reliability boards capable of operating in extreme environments.

Manufacturing Challenges

Supply chain disruptions and material shortages present ongoing challenges. Copper-foil price volatility and structural shortages of high-frequency laminates create capacity constraints. Labor shortages in specialized areas like microvia drilling require increased automation and AI-assisted processes.

Memory manufacturers reallocate resources toward high-margin products like HBM and DDR5, compressing traditional DRAM and NAND Flash supply used in consumer devices. This creates cost pressures across the electronics supply chain. Geopolitical tensions and regulatory complexities drive manufacturers to introduce advanced technologies like digital twins and AI-driven analytics to enhance visibility, traceability, and accountability.

Quality control requires rigorous testing protocols including thermal cycling, vibration testing, and accelerated aging. Statistical process control monitors critical parameters with tight tolerances—via diameter variations under ±10% and copper weight consistency within ±15%.

The gap between standard PCB shops and advanced technology manufacturers continues widening. Manufacturing these advanced technologies requires specialized equipment, expertise, material flexibility (Rogers RO4350B, LCP, paper-based substrates), process capabilities (minimum trace/space, via diameter, layer registration accuracy), and comprehensive testing and validation.

Manufacturing Process Advancements

Photolithography transfers geometric patterns onto substrates, creating fine conductive tracks. Laser drilling creates extremely small, precise vias essential for connecting multiple layers in HDI boards. Automated Optical Inspection (AOI) systems detect defects in vias, traces, and connectivity.

Modified semi-additive processing (mSAP) enables line widths under 25 µm for ultra-dense routing. Sequential build-up technology allows precise layer-by-layer construction. These techniques deliver faster production and higher-quality boards meeting demanding specifications.

Smart PCBs with Integrated Functionality

Smart PCBs integrate sensors, connectivity features, and processing capabilities directly into the board structure. These boards can monitor their own performance, detect faults, and communicate status information. Applications include self-diagnostic systems, condition monitoring in industrial equipment, and health monitoring in medical devices.

Smart PCB technology represents the convergence of traditional circuit board functionality with emerging sensor and communication technologies, enabling new product categories and applications.

Industry Investment and Capacity Expansion

Major manufacturers including TTM Technologies, AT&S, and Unimicron continue investing in advanced technologies and expanded capacity. AT&S announced a $1.98 billion investment in Malaysia (2022-2026) focused on advanced HDI and IC substrate technologies. TTM Technologies committed up to $130 million for a New York manufacturing facility supporting AI and high-performance computing applications.

These investments reflect industry confidence in continued demand for advanced PCB technologies despite supply chain challenges and economic uncertainties. Manufacturers recognize that competitive advantage will increasingly depend on advanced capabilities rather than commodity production.

Future Outlook

The printed circuit board industry stands at the intersection of multiple technology trends. AI-driven design automation, HDI adoption, advanced materials, and sustainable manufacturing practices are reshaping the competitive landscape.

As boards become more complex—with 124-layer prototypes already demonstrated by OKI Circuit Technology for AI semiconductor testing—the industry must balance performance requirements with environmental responsibility. The shift toward biodegradable materials like Soluboard®, combined with AI-assisted manufacturing efficiency, positions the industry for sustainable growth.

The global smart home market is expected to reach over $150 billion by 2026, with millions of connected devices relying on advanced PCB solutions. This growth, combined with automotive electrification, 5G infrastructure deployment, and IoT expansion, ensures continued strong demand for boards that are smaller, faster, and more environmentally responsible.

The convergence of miniaturization, enhanced performance, and environmental responsibility will define the next chapter of PCB technology. Whether through improved signal integrity for 5G networks, thermal management for EVs, or biodegradable materials reducing e-waste, boards will remain foundational to electronics advancement for years to come.