Innovations in Rope Access Equipment: Materials, Safety, and Lifecycle Management

Rope access is a method used worldwide for work at height in industries such as wind energy, construction, oil and gas, and infrastructure maintenance. The effectiveness and safety of these operations depend heavily on the equipment technicians use. Over the past decade, manufacturers and industry bodies have introduced changes in materials, design, and digital management tools that have reshaped the capabilities and reliability of rope access gear. This article outlines the major, widely adopted innovations in rope access equipment and the context in which they developed.

Table Of Content

- Material Advancements in Load-Bearing Components

- Ergonomics and Human Factors Engineering

- Integrated Safety and Sensing Technologies

- Modular and Configurable System Design

- Equipment Lifecycle Management and Digital Records

- Sustainability and Life Extension Practices

- Training Standards for New Equipment Types

- Equipment Testing and Certification Frameworks

- Summary

Material Advancements in Load-Bearing Components

The physical performance of rope access equipment is determined primarily by the materials used in its construction. Recent industry-wide shifts have seen wider adoption of high-performance synthetic fibers and composites in place of traditional steel and standard nylon.

One material group that has become a baseline standard in high-end harnesses, lanyards, and connector components is high-modulus polyethylene (HMPE), often referred to by brand names such as Dyneema or Spectra. HMPE offers a high strength-to-weight ratio and floats in water, making it suitable for marine and offshore environments. It also exhibits low stretch under load, which improves positioning accuracy for technicians.

Carbon fiber composites have also entered the market for rigid components such as ascenders, descenders, and pulley side plates. These components are lighter than their aluminum and steel predecessors while maintaining comparable tensile strength and fatigue resistance. The weight reduction directly reduces the physiological load on the technician during prolonged shifts or long ascents.

Ergonomics and Human Factors Engineering

Beyond raw material properties, equipment designers now systematically apply ergonomic data to reduce the risk of musculoskeletal strain. Harness designs have moved away from narrow, unpadded webbing toward contoured waist belts and leg loops that distribute suspension forces across larger surface areas.

Glove design is another area where user feedback has driven change. Modern rope access gloves incorporate textured synthetic palms that maintain grip in wet or oily conditions while allowing sufficient dexterity for knot tying and equipment adjustment. Some models integrate impact protection over the knuckles and fingers without adding significant bulk.

Adjustable bridge systems on harnesses now allow technicians to shift their center of gravity while suspended, reducing lower back fatigue during tasks that require leaning backward or reaching overhead.

Integrated Safety and Sensing Technologies

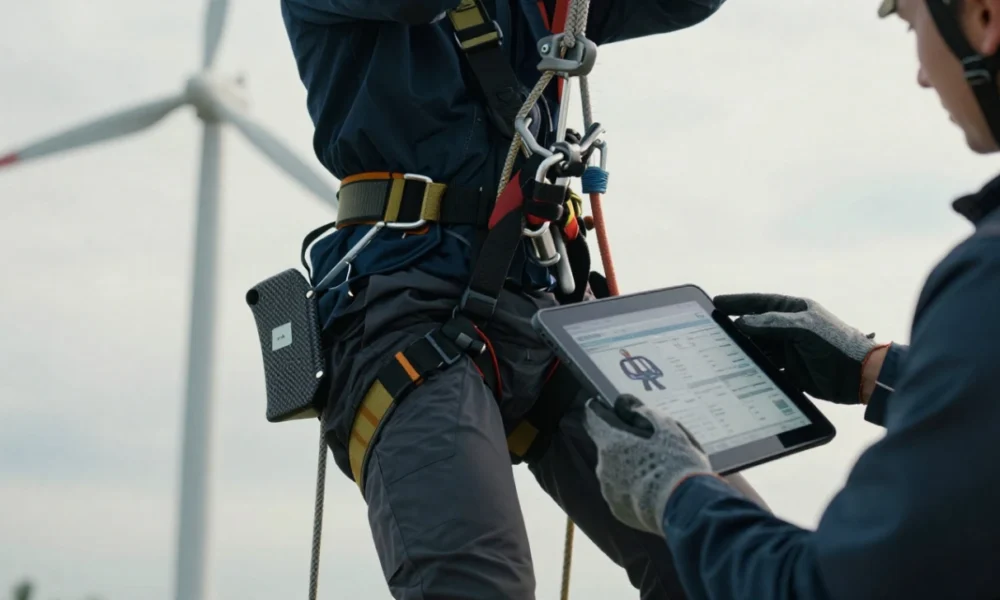

Equipment manufacturers have introduced non-invasive technologies that support situational awareness and inspection compliance. One such innovation is the embedding of passive RFID tags into soft goods such as harnesses, lanyards, and rope protectors. These tags do not actively track location or biometric data; rather, they store a unique identifier that can be read by a handheld scanner or mobile device.

The primary function of RFID integration is to facilitate digital equipment registers. Inspection dates, service history, and assignment records can be linked to each physical item, reducing reliance on paper logs and manual data entry. This approach helps organizations comply with equipment traceability requirements set by bodies such as IRATA and SPRAT.

Some fall arrest harnesses now feature load-indicating webbing or built-in shock pack deployment indicators. These visual markers permanently change appearance if the equipment has experienced a fall event or exceeded its design load, providing a clear, non-destructive indication that the item must be removed from service.

Modular and Configurable System Design

The variety of environments in which rope access is used has driven demand for equipment that can be reconfigured rather than replaced. Modular harness systems allow the user to swap out specific components—such as dorsal attachments, side D-rings, or chest ascender bridges—depending on the task.

Industrial rope access ascenders and descenders are increasingly designed with field-replaceable wear components. Cam surfaces, friction posts, and guide rollers can be exchanged without special tools, extending the useful life of the main housing. This approach reduces waste and lowers the total cost of ownership for companies managing large inventories.

Multi-configuration anchor slings and positioning lanyards now use adjustable webbing and multiple attachment points, enabling the same piece of equipment to function as a cowstail, an anchor strap, or a work-positioning tether depending on how it is rigged.

Equipment Lifecycle Management and Digital Records

The digitization of equipment management has progressed from optional software to common practice among large contractors and regulated industries. Cloud-based asset management platforms allow safety managers to view the status of every harness, helmet, rope, and descender across multiple job sites.

These systems typically record:

- Purchase date and manufacturer

- Inspection dates and inspector identification

- Notes on wear or damage

- Retirement date based on manufacturer guidelines or regulatory intervals

Barcode and RFID scanning allow technicians to perform field inspections and update records immediately using a smartphone or dedicated reader. This integration reduces the risk of equipment exceeding its service life without documented inspection.

Sustainability and Life Extension Practices

Environmental considerations have influenced both manufacturing processes and equipment retirement policies. Several major manufacturers now offer webbing and rope made from recycled fibers, particularly in non-load-bearing components such as padding covers and equipment bags.

The concept of circularity has gained traction. Instead of discarding retired harnesses and ropes, some organizations participate in take-back schemes where materials are reprocessed into industrial products such as bumpers or decking. This practice is more prevalent in regions with extended producer responsibility regulations.

Remanufacturing is another emerging practice. Certain metal components, such as descender bodies and carabiners, can be disassembled, cleaned, non-destructively tested, refinished, and fitted with new wear parts before being certified for a second service life. This process is distinct from informal refurbishment and is governed by strict original equipment manufacturer protocols.

Training Standards for New Equipment Types

As equipment becomes more specialized, training programs have expanded to include familiarization with specific material properties and mechanical features. Industry training standards now commonly include modules on:

- Inspection of composite and synthetic fiber components for hidden damage

- Proper adjustment of ergonomic harness features

- Use of digital inspection tools and asset management software

- Maintenance of modular systems in field conditions

Certification bodies require that technicians demonstrate competence with the specific models of equipment provided by their employer, rather than generic device classes. This shift acknowledges that operational safety depends on user familiarity, not only on theoretical knowledge.

Equipment Testing and Certification Frameworks

Regulatory and industry standards have evolved to address the unique characteristics of modern materials and designs. In Europe, harmonized standards under the Personal Protective Equipment Regulation now include specific test methods for HMPE slings and carbon fiber connectors. These methods account for factors such as low elongation and sensitivity to edge sharpness that differ from legacy metal and nylon equipment.

Certification marks from notified bodies provide purchasers with assurance that equipment meets published performance criteria. Third-party testing remains the primary mechanism for verifying compliance, although manufacturers increasingly publish detailed technical data sheets and user instructions in digital formats accessible via QR codes on the equipment label.

Summary

Rope access equipment continues to develop along several parallel tracks: materials science, ergonomics, digital traceability, and service-life extension. These innovations share a common foundation in verifiable engineering data and field feedback rather than speculative concepts. For organizations and technicians, the practical outcome is equipment that is lighter, more comfortable to wear, more traceable throughout its life, and more adaptable to diverse work environments. Staying informed about these changes remains essential for those responsible for specifying, inspecting, and using rope access gear.